面向机翼线缆支架的装配符合性视觉检测

打开文本图片集

中图分类号:TP391 文献标识码:Adoi:10. 37188/OPE. 20253307. 1130

CSTR:32169. 14. OPE. 20253307. 1130

Visual inspection for assembly conformity of wing cable brackets

WANG Xin,LI Pengcheng,CUI Haihua*,GE Xinxin (College of Mechanical & Electrical Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing ,China) * Corresponding author,E-mail:cuihh@nuaa. edu. cn

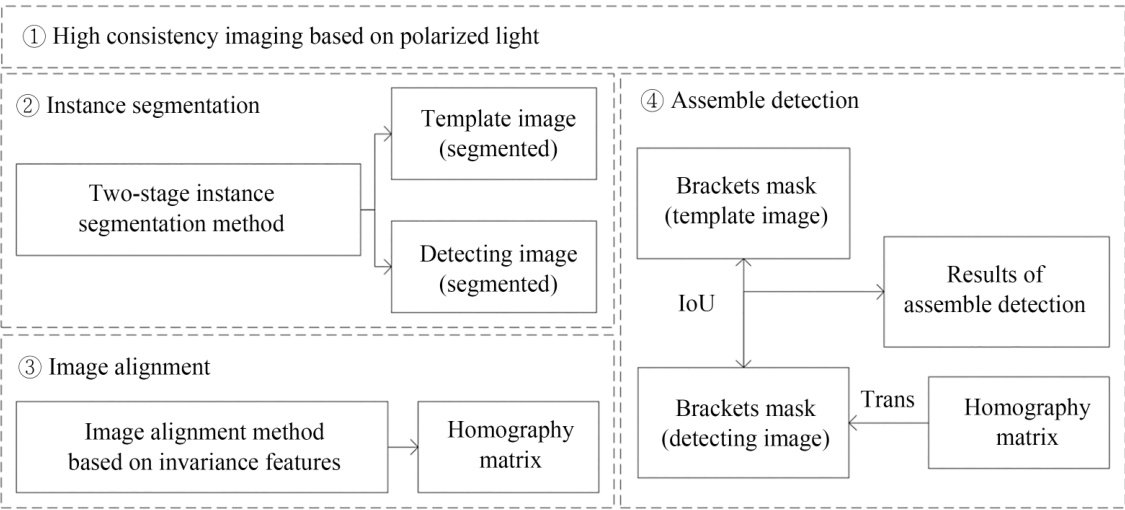

Abstract:To ensure assembly quality,traditional methods rely on manual visual inspection,which often suffers from limited stability and accuracy. Addressing the limitations of existing assembly inspection tech⁃ niques,a vision-based compliance inspection method for wing cable bracket assembly is proposed. To mit⁃ igate missing image information caused by strong reflections from metal brackets,polarization imaging technology is employed to enhance the imaging quality. To resolve the challenge of mixed foreground and background information in the assembly scene,a two-stage instance segmentation algorithm is developed by integrating YOLOv8 with SAM,enabling rapid deployment and precise part segmentation. To com ⁃ pensate for viewpoint discrepancies resulting from repeated positioning errors between the actual standard and the assembly drawing,invariant features are extracted for image alignment. Finally,pixel-level mask intersection over union(IoU)metrics between corresponding parts are calculated to identify incorrect or missing assemblies. Compared to manual inspection,the proposed method substantially improves inspec⁃ tion efficiency. Experimental results validate its effectiveness,demonstrating an accuracy of 96.08% and a recall rate of 100% for misassembled parts,thereby confirming its high deployment efficiency,accuracy, and robustness.

Key words:visual inspection;instance segmentation;template matching;cable bracket;polarization im aging

1 引 言

装配质量的控制在航空工业领域具有重要意义,是飞行器安全稳定工作的基石[1]。(剩余13142字)