激光跟踪仪主动对准式复合传感高精度姿态测量

打开文本图片集

中图分类号:TH721;TH744 文献标识码:Adoi:10. 37188/OPE. 20253307. 1007 CSTR:32169. 14. OPE. 20253307. 1007

High-precision attitude measurement with active aiming composite sensing for laser tracker

CHENG Zhi 1,2 ,DONG Dengfeng 1,2 ,LI Yang1*,QIU Qifan 1,3 ,WANG Jianguo 1,2 , HUO Hanlin1,HUANG Yunpeng 1,2 ,ZHOU Weihu1,2

(1. Institute of Microelectronics,Chinese Academy of Sciences,Beijing 100029,China; 2. University of Chinese Academy of Sciences,Beijing 101408,China; 3. College of Automation Engineering,Nanjing University of Aeronautics and Astronautics, Nanjing ,China) * Corresponding author,E-mail:liyang@ime. ac. cn

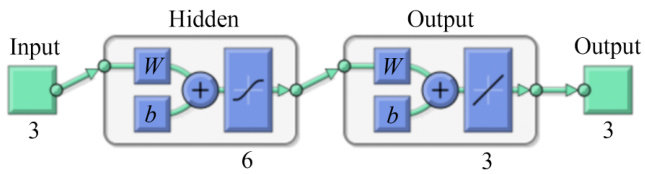

Abstract:To address the requirements of quality inspection and assembly process control in large-scale high-end equipment manufacturing,an active aiming-based attitude measurement target for laser trackers was developed. A comprehensive mathematical model for attitude measurement was established,accom ⁃ panied by parameter calibration procedures and nonlinear error compensation methods. The structural com ⁃ position,operational principles,coordinate system definitions,and data acquisition and preprocessing tech⁃ niques of the active aiming target were systematically presented. Attitude-solving models were constructed based on constraints derived from laser beam vectors and gravitational vectors. Furthermore,a feedfor⁃ ward neural network was employed to compensate for nonlinear errors inherent in the model-derived atti⁃ tude data. Calibration strategies for parameter matrices and neural network training were formulated and evaluated. Experimental validation,including parameter calibration and attitude measurement,was per⁃ formed using the active aiming target. The results indicate that within a 15m range,the root-mean-square deviation between the proposed target and a Leica T-MAC sensor is 0.030∘ ,satisfying the precision re⁃ quirements for typical industrial large-scale attitude measurements.

Key words:attitude measurement;laser tracker;parameter fusion;active aiming;inertial sensing

1 引 言

随着大型高端装备制造朝着质量控制精细化、制造过程自动化方向发展,传统的三自由度激光跟踪测量技术已经难以满足大尺寸部件的制造检测需求[1-2],特别是在飞行器大型部件装配位姿引导、自动焊接/钻铆/车削机器人末端执行机构精确定位、重型燃气轮机部件装配参数现场测量、高铁转向架部件制造与装配质量检验、大型多轴机床空间误差补偿等高性能检测场景中,迫切需要采用具备高精度三维坐标和三维姿态测量能力的六自由度测量技术[3-6],对被测目标的位姿状态进行完整表征。(剩余15485字)